1. Background

Oil has been called the "Blood of industry" and "Black gold",It affects the modern industrial system and our daily lives, but the economic situation of the world's energy has caused oil production companies to face huge pressure for sustainable development,And under the current theme of "Carbon neutrality" and "Carbon peak",energy conservation, emission reduction, cost reduction and efficiency improvement have become issues that today's oilfield companies must pay attention to when seeking further development.

2. GD350-13 Series VFD for oil pumping unit

Pumping units are important equipment for oilfield enterprises to carry out production activities.At the same time, a large amount of energy is consumed in its production process.The energy-saving technology will be assessed on the operating environment of the pumping unit to meet the requirements of the energy-saving development model of oilfield enterprises.

Therefore, INVT follows the development needs of the industry and launches GD350-13 Series VFD for oil pumping unit. It integrates special functional designs for beam pumping units, plateau pumps, tower pumping units and direct-drive screw pumps to help oilfield companies reduce costs and increase efficiency, and promote their sustainable development.

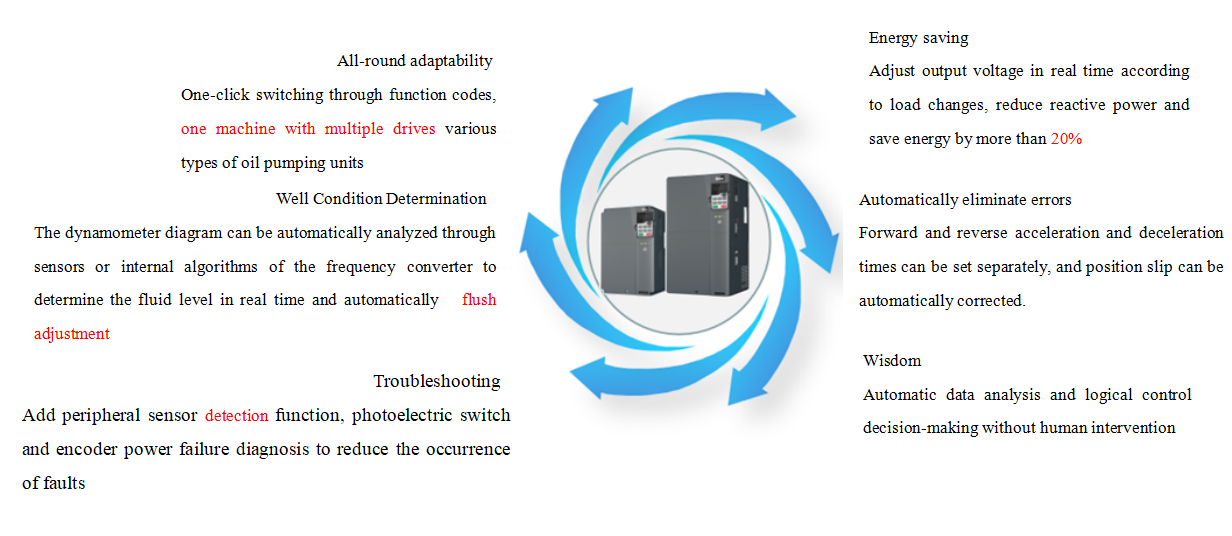

* Features of GD350-13:

- Energy conservation and efficiency,reduces reactive power in real time according to load changes, saving more than 20% of power under extreme working conditions compared with the previous generation;

Omni-Adaptive,integrates specialized control functions for all types of pumping units, such as traveler beam, tower, and direct-drive screw pumps;

- Mine surveillance,support sensor or sensorless algorithms to realize the function of power indication, real-time monitoring of the status of wells and mines, and automatic adjustment according to the power indication diagram;

- Automated platoon mining,enter into sleep and wake-up state by external signal or time setting, and can perform low-power swinging action at the optimal balance position to avoid sudden start-up causing danger to human beings and over-current alarm;

- High energy efficiency ratio,support fluid level control for stroke and travel adjustments to improve pumping efficiency in pumping units;

- Specialized brake unit control logic for a safer system and longer service life;

- Highly scalable,support 3 expansion interfaces, multiple types of expansion cards, and any card slot installation;

- Configuration richness,All 380V voltage class products are equipped with built-in braking unit and STO safety torque cut-off function as standard, which makes the application safer and more reliable;

- Support both synchronous and asynchronous motor drives;

3. GD350-13 Specialized Machine Feature

* Beam pumping unit

- flexible control

- up and down speed separation

- pumping balance rate calculation and reminder

- Swing inter-pumping function

- Super energy saving function

- Brake unit stopping delay

- Flush count display and setting

- Automatically adjusts the stroke

- Support with or without sensor to show power function

* Tower pumping unit

- Reciprocating motion

- Position correction and emergency stop function

- Hover mode

- Up and down speed separation

- Brake unit stop delay

- Travel self-learning and start-up home position finding

- Drive high pole logarithm permanent magnet synchronous motor

- Balance rate indication, stroke display and setting

* Direct Drive Progressive Cavity Pump

- Safety protection

-Torque release

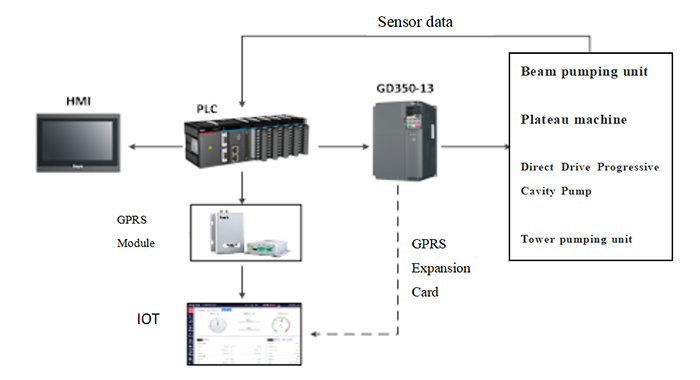

4. INVT pumping machine solution case

*

* Program Advantage

Summary:

After practical verification in the field, INVT GD350-13 series pumping machine special inverter gives full play to the working capacity of the pumping machine, while the energy saving effect and specialized functions well meet the needs of customers.

INVT has rich industry experience and solid technical reserves in the industrial control industry.Always adhere"Market-oriented, customer-centered",comply with industry development trends, gain insight into industry dynamics, go deep into the front end of the market, understand customer needs, and dig deep into industry processes. As the needs of oilfield companies continue to increase,INVT will also continue to work hard to provide customers with products with superior performance, stability and reliability.

Our site uses cookies to provide you with a better onsite experience. By continuing to browse the site you are agreeing to our use of cookies in accordance with our Cookie Policy.